IZOFLEX - Instruction

HOW TO DISPOSE IZOLEX

According to ITB 408/2006 instruction hydro-insulations with damp-proof membrane IZOFLEX are made when the building is situated over underground water level in permeable soil. For IZOFLEX to perform its functions the following conditions must be fulfilled:

- tightness on overlaps must be assured

- the horizontal edge of the IZOFLEX on the surface of the wall must be sealed

- places where IZOFLEX is connected with horizontal insulation and where IZOFLEX is folded must be sealed

Basic rules

Damp-proof membrane IZOFLEX is disposed vertically - “buckets” must be put to the wall. In horizontal applications “buckets” must be put down.

During laying next stripes of IZOFLEX are connected with overlaps. The width of overlap depends on application. The shape of “buckets” makes this connection easy because cones on the laps easily fit into each other, making the connection precise even under the influence of slight pressure.

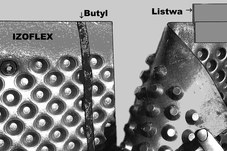

In vertical applications the vertical (side connections) overlaps must be 3-5 rows depending on application and the horizontal (top-bottom connections) overlaps can be 2-4 rows. The shorter overlaps are used when connection is supported by glue (draw 1) or two-side adhesive tape (e.g. butyl tape) and wider overlaps are used in connections without glue or tape. E.g. 3 cones it ca 10cm, 5 cones is ca 15cm and 10 cones is an overlap 30cm. The basic overlap without glue or tape is 15 cm.

In horizontal applications of IZOFLEX (e.g. terraces) all the overlaps must be the same and should be 3-4 rows. In most of cases fixing of IZOFLEX is necessary during laying only and is an auxiliary element because after mounting IZOFLEX is banked with earth or flooded with concrete

The type of application determines the selection of fastening details. Damp-proof membrane IZOFLEX can be fixed by dowels, screws or nails, preferably with special nails with washer (we have special nails IZOFIX in our offer). Other practical fixing is acceptable as well. In some cases it is enough cover the foil with soil using temporary supports to support the foil during backfilling. After filling the trench the edge of IZOFLEX that is over the ground can be cut to the level of foundation or ground. Where is required the edge of IZOFLEX can be finished with special profile (finishing board)

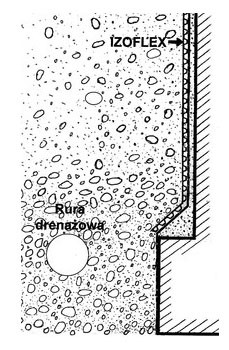

Izoflex should be fixed above the moisture seal depending on the type foundation. Depending on the degree of water’s threat and the purpose of basement in the building you can choose the proper system of materials that constitute protection against water. If there are such requirements in the project you have to make the proper drainage around the building (rys2). The vertical, drainage and filtering layers (gravel, sand etc.) should be put min. 0,5 m from the protected foundation or wall. Their granularity should be similar to the soil structure.

The drainage pipe needs to be covered on all sides with seepage material with thickness min 20cm (gravel, grit or granulated slag). The drainage pipe should be placed so that its top doesn’t protrude above the upper edge of the foundation footing. The slope of pipe must be 0,5% and in most cases diameter 120-125mm is enough.

Because of threat of rising damp by spatter water and forming of puddles along the building should be zone of gravel – width 50cm, depth 20cm.

Additional notes

The wider the overlap strip, the more difficult it is to level out unevenness of the ground (deviation from flatness) and the connection is all the stiffer. Hence the conclusion that in the case of a corrugated substrate, smaller overlaps should be used and a narrow adhesive tape (e.g. butyl) should be used and the overlap should be pressed with additional tight fastenings.

There is a problem with cleanliness during earthworks - some contamination (earth or sand) may always get under the overlap. This may be important for the tightness of the IZOFLEX layer - it depends on the application and the type of water hazard.

The specific method of operation of the IZOFLEX foil is its double action: the foil insulates and creates a ventilation and drainage layer. The use of these properties depends on the method of use specified in the design of the building or structure.